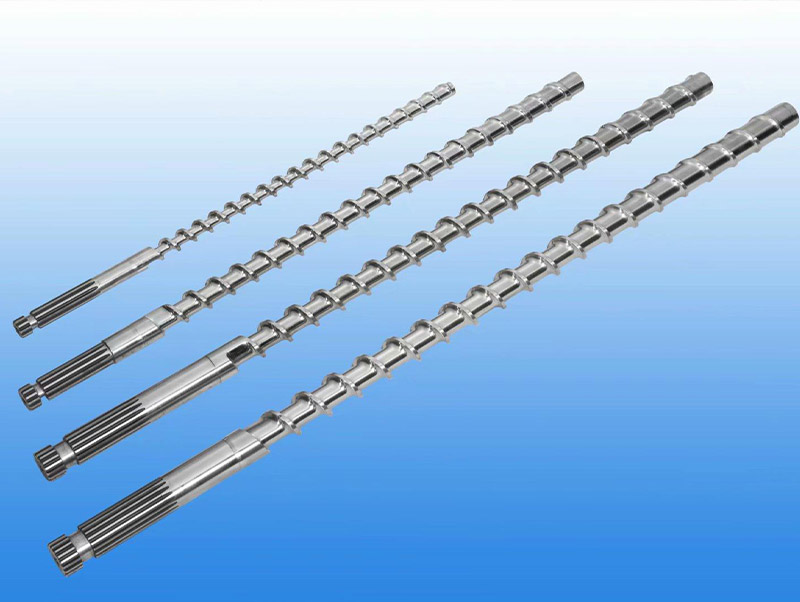

Спиральный пескоструйный шкаф

10 / 08 / 2021

10 / 08 / 2021винтовой экструдер

1. Применение

Широко используется для обработки различных экструзионных поверхностей винтов без повреждения винтов.

2. Особенности

Машина оснащена регулируемым циклонным сепаратором, который может выделять хороший абразив из смеси для рециркуляции, что значительно снижает расход абразива.

Пыль будет вдыхаться в наш мешковый пылеуловитель, так что шкаф хорошо проветривается и оператор хорошо видит.

Тяжелые износостойкие резиновые перчатки, защищающие оператора, имеют длительный срок службы.

Быстрая замена стеклянных окон не требует замены инструментов.

Регуляторы сжатого воздуха и манометры позволяют изменять взрывное давление в зависимости от применения.

Высокопроизводительные пистолеты под давлением обеспечивают более быструю и эффективную очистку.

Гранулы пригодных абразивов: позиции 36 - 320.

3. Принцип работы

Это пескоструйная машина под давлением, состоящая из пескоструйной камеры, системы абразивного цикла и пылеуловителя. Используя сжатый воздух в качестве движущей силы, создавая рабочее давление, абразив всасывается в распылитель и ударяется о поверхность заготовки. Он имеет высокое рабочее давление и количество таблеток.

Система абразивного цикла: использованный абразив подается винтом в подъемник, затем подается в сепаратор, хороший абразив перерабатывается в бункер для следующей пескоструйной обработки, отходы и пыль извлекаются в пылеуловитель.

4. Основные технические нормы

Нет, нет. | Модель | TS3210 - 3P | ||

1. | Максимальный диаметр винта | |||

2. | Рекомендуемые абразивы | Грецкие орехи | ||

3. | Размер | L3200 мм * W1000 мм * H2250 мм | ||

4. | Взрывная система | Количество огнестрельного оружия | Три. | |

сопловой материал | Карбид бора | |||

5. | Загрузочная способность | |||

6. | Метод блокировки и вращения деталей | Количество | 1 комплект | |

Вращающаяся система | Автоматический | |||

Электричество | 0.4 кВт (переменная скорость) | |||

7. | Подвал крепления | Количество | 1 комплект | |

Переместить | В зависимости от длины изделия; Система блокировки ленты | |||

Механизмы | Два ведомых валка (полиуретановое покрытие) | |||

8. | АКС артиллерийская эксплуатационная система | Количество | 1 комплект | |

Мобильная система | Вперед и назад (управляется редуктором) | |||

Электричество | 400W (трансмиссия) | |||

Девять. | Пескоструйный баллон | Диаметр | 600 мм | |

Громкость | 0,3 м³ | |||

Способ подачи абразива | Автоматический | |||

Десять. | абразивная циркуляционная система | Нижний винт | Capacity | 15ton/h |

Power | 0.75kw | |||

Elevator | Capacity | 15ton/h | ||

Power | 1.5kw | |||

11 | Dust Collector | Dust Cleaning Method | Automatic Pulse Jet Cleaning System | |

Capacity | 6677~13353m3/h | |||

Qty of Cartridge | 4pcs; Φ350mm x H1000mm | |||

Fan Power | 4kw | |||

12 | Machine Internal Light | 0.025kw x 4pcs | ||

13 | Total Power | Elevator 1.5kw |

| |

Screw Conveyor 0.75kw | about 7.2kw | |||

Rotate System 0.4kw | ||||

Running System 0.4kw | ||||

Fan 4kw | ||||

Light 0.025kw x 4pcs | ||||

14 | Compressed Air Supply | Working Pressure | 0.6-0.7Mapa; | |

Air Consumption | 5-6m3/min/gun | |||

15 | Power Supply | 380V ±10% 50Hz | ||

16 | Noise Level | ≤85dBA | ||

17 | Dust emission | ≤80mg/m3 | ||

Note: our equipment can be designed according to customer special requirements